- KHO SÀN GỖ QUẬN 2 91 Lương Định Của, Phường Bình An, Quận 2, HCM

Tel/Zalo: 0946 8888 91 - KHO SÀN GỖ QUẬN 6 68A Đặng Nguyên Cẩn, Phường 14, Q6, HCM

Tel/Zalo: 097 8888 395 - KHO SÀN GỖ QUẬN 7 444A Nguyễn Văn Linh, Tân Phú, Quận 7, HCM

Tel/Zalo: 091 8888 923 - KHO SÀN GỖ QUẬN 8 146 Phạm Hùng, X. Bình Hưng, Bình Chánh, HCM

Tel/Zalo: 091 8888 315 - KHO SÀN GỖ QUẬN 9 15 Dương Đình Hội, Phước Long B, Quận 9, HCM

Tel/Zalo: 091 8888 951 - KHO SÀN GỖ QUẬN 10 209 Tô Hiến Thành, Phường 13, Quận 10, HCM

Tel/Zalo: 0913 8888 01 - KHO SÀN GỖ QUẬN 12 484 Nguyễn Văn Quá, Đông Hưng Thuận, Quận 12, HCM

Tel/Zalo: 0913 8888 20 - KHO SÀN GỖ BÌNH TÂN 254 Nguyễn Thị Tú, Bình Hưng Hoà B, Bình Tân, HCM

Tel/Zalo: 084 8888 254 - KHO SÀN GỖ BÌNH CHÁNH 114 Đường số 12 KDC Phong Phú 4, Bình Chánh, HCM

Tel/Zalo: 090 8888 795 - KHO SÀN GỖ BÌNH THẠNH 443 Bạch Đằng, Phường 2, Quận Bình Thạnh, HCM

Tel/Zalo: 091 8888 443 - KHO SÀN GỖ CỦ CHI 410 Tổ 1, Khu Phố 4, Tỉnh lộ 8, Củ Chi, HCM

Tel/Zalo: 091 8888 755 - KHO SÀN GỖ GÒ VẤP 957 Phan Văn Trị, Phường 7, Quận Gò Vấp, HCM

Tel/Zalo: 092 8888 181 - KHO SÀN GỖ HÓC MÔN 249 Tô Ký, Tân Xuân, Hóc Môn, HCM

Tel/Zalo: 079 8888 249 - KHO SÀN GỖ KHA VẠN CÂN 867 Kha Vạn Cân, Linh Tây, Thủ Đức, HCM

Tel/Zalo: 081 8888 528 - KHO SÀN GỖ NHÀ BÈ số 9 Nguyễn Hữu Thọ, Phước Kiển, Nhà Bè, HCM

Tel/Zalo: 089 8888 081 - KHO SÀN GỖ PHÚ NHUẬN 270/10 Nguyễn Trọng Tuyển, Phường 8, Phú Nhuận, HCM

Tel/Zalo: 091 8888 174 - KHO SÀN GỖ TÂY HÒA 137A Tây Hoà, Phước long A, Quận 9, Thủ Đức, HCM

Tel/Zalo: 085 888 8067 - KHO SÀN GỖ QUẬN TÂN BÌNH 760 Lạc Long Quân, Phường 9, Quận Tân Bình, HCM

Tel/Zalo: 091 88888 75 - KHO SÀN GỖ TÂN BÌNH 355 Cộng Hòa, Phường 13, Quận Tân Bình, HCM

Tel: 091 8888 032 - KHO SÀN GỖ TÂN PHÚ 249 Trần Thủ Độ, Phú Thạnh, Tân Phú, HCM

Tel/Zalo: 090 8888 916 - KHO SÀN GỖ TÂN THÀNH 51 Lê Đình Thụ, Tân Thành, Tân Phú, HCM

Tel/Zalo: 090 8888 240 - KHO SÀN GỖ TÂN TẠO 429/39 Chiến Lược, P. Bình Trị Đông A, Bình Tân, HCM

Tel/Zalo: 091 8888 721 - KHO SÀN GỖ THỦ ĐỨC 610 Quốc Lộ 13, Hiệp Bình Phước, Thủ Đức, HCM

Tel/Zalo: 081 8888 610 - KHO SÀN GỖ THỦ ĐỨC(Tam Phú) 234 M Tam Bình, Tam Phú, Thủ Đức, HCM

Tel/Zalo: 090 848 0002 - KHO SÀN GỖ CẦN GIỜ 2795 Huỳnh Tấn Phát, Ấp 6, Phú Xuân, Nhà Bè, HCM

Tel/Zalo: 089 8888 723 - KHO SÀN GỖ SÀI GÒN 223 Phan Huy Ích, Phường 14, Gò Vấp, HCM

Tel/Zalo: 091 8888 223

- KHO SÀN GỖ HÀ NỘI 342 Giải Phóng, Phương Liệt, Thanh Xuân, Hà Nội

Tel: 091 8888 601 - KHO SÀN GỖ HÀ ĐÔNG Số 01, BT5 Khu đô thị Phú Lương, Hà Đông, Hà Nội

Tel: 091 8888 619 - KHO SÀN GỖ TÂY HỒ 586 Lạc Long Quân, P. Nhật Tân, Q. Tây Hồ. Hà Nội

Tel: 091 8888 927 - KHO SÀN GỖ SÓC SƠN 68 Đường 16, Thôn Phú Thọ, Đông Xuân, Sóc Sơn, Hà Nội

Tel: 091 8888 561 - KHO SÀN GỖ MỸ ĐÌNH 123 Nguyễn Văn Giáp, Nam Từ Liêm, Hà Nội

Tel: 091 8888 122 - KHO SÀN GỖ LONG BIÊN 583 Ngô Gia Tự, Đức Giang, Long Biên, Hà Nội

Tel: 091 8888 270

- KHO SÀN GỖ ĐÀ NẴNG 65 Võ Chí Công, Hòa Xuân, Cẩm lệ, Đà Nẵng

Tel: 093 8888 957 - KHO SÀN GỖ CẨM LỆ ĐÀ NẴNG 34 Ông Ích Đường, Thọ Hòa Tây, Cẩm Lệ, Đà Nẵng

Tel: 091 8888 715 - KHO SÀN GỖ HÒA XUÂN ĐÀ NẴNG 113C Võ Chí Công, Hòa Xuân, Cẩm lệ, Đà Nẵng

Tel: 091 8888 473

- KHO SÀN GỖ BIÊN HÒA 126B, Quốc Lộ 1A, khu phố 4, Tân Hiệp, Biên Hòa, Đồng Nai

Tel/Zalo: 089 8888 005 - 091 8888 647 - KHO SÀN GỖ TRẢNG BOM Số 5/4 Lộc Hoà, QL1A, Tây Hoà, Trảng Bom, Ðồng Nai

Tel/Zalo: 091 8888 061 - KHO SÀN GỖ LONG THÀNH Tổ 10 Phạm Văn Đồng, khu Cầu Xéo, Long Thành, Đồng Nai

Tel/Zalo: 091 8888 146 - KHO SÀN GỖ GIA KIỆM 35/2E Quốc lộ 20, Thống Nhất, Ðồng Nai

Tel: 090 8888 635 - KHO SÀN GỖ XUÂN LỘC 404 Hùng Vương, Gia Ray, Xuân Lộc, Đồng Nai

Tel: 081 8888 433 - KHO SÀN GỖ ĐỊNH QUÁN 54 Phố 2, Ấp 3, Phú Lợi, Định Quán, Đồng Nai

Tel: 081 8888 764 - KHO SÀN GỖ LONG KHÁNH Số 1 Quốc Lộ 1A , Đường 21 tháng 4 , KP Núi Tung , TP. Long Khánh , Đồng Nai

Tel: 085 8888 781

- KHO SÀN GỖ BÀ RỊA 75 Nguyễn Tất Thành, Phước Nguyễn, Bà Rịa, Bà Rịa - Vũng Tàu, Vietnam

Tel/Zalo: 0813 9999 72

- SHOWROOm SÀN GỖ VŨNG TÀU 170A Huyền Trân Công Chúa, Phường 8, Vũng Tàu

Tel: 091 8888 165 - KHO SÀN GỖ VŨNG TÀU 117 Huyền Trân Công Chúa, Phường 8, Vũng Tàu

Tel: 081 8888 165

- KHO SÀN GỖ BÌNH DƯƠNG 62 Phạm Ngọc Thạch, Hiệp Thành, Thủ Dầu Một, Bình Dương

Tel/Zalo: 089 8888 062 - 090 8888 062

- KHO SÀN GỖ BÌNH PHƯỚC 729 Quốc lộ 14, Tân Bình, Đồng Xoài, Binh Phước

Tel/Zalo: 089 8888 729 - 090 8888 193

- KHO SÀN GỖ TÂY NINH 445 Lạc Long Quân, Hiệp Tân, Hoà Thành, Tây Ninh

Tel: 089 8888 250 - KHO SÀN GỖ TRẢNG BÀNG 244A Nguyễn Văn Rốp, Trảng Bàng, Tây Ninh

Tel: 070 8888 170

- KHO SÀN GỖ KHÁNH HÒA 442 Lê Hồng Phong, Phước Hải, Nha Trang, Khánh Hoà

Tel: 090 8888 906 - KHO SÀN GỖ NHA TRANG B1 Chung Cư Lê Hồng Phong, Phước Hải, Nha Trang, Khánh Hoà

Tel: 091 8888 997

- KHO SÀN GỖ LA GI Số 4 Nguyễn Trường Tộ, Phường 10, Lagi, Bình Thuận

Tel: 090 8888 085 - KHO SÀN GỖ PHAN THIẾT 64 Đại Lộ Hùng Vương, Phú Thủy, Phan Thiết

Tel: 091 8888 742

- KHO SÀN GỖ PHAN RANG 95 QL1, Ngã 3 Long bình, Ninh Phước, Phan Rang, Ninh Thuận

Tel: 082 8888 095

- KHO SÀN GỖ BẢO LỘC 15B Nguyễn Văn Cừ, Lộc Sơn, Bảo Lộc, Lâm Đồng

Tel: 090 8888 053 - KHO SÀN GỖ ĐỨC TRỌNG 358 Quốc Lộ 20, Liên Nghĩa, Đức Trọng, Lâm Đồng

Tel/Zalo: 090 8888 053 - KHO SÀN GỖ ĐÀ LẠT 29A Xô Viết Nghệ Tĩnh, Phường 7, Đà Lạt, Lâm Đồng

Tel/Zalo: 091 8888 506

- KHO SÀN GỖ GIA LAI 373 Phạm Văn Đồng, Pleiku, Gia Lai

Tel/Zalo: 089 8888 373 - 091 8888 350 - KHO SÀN GỖ PLEIKU 30/12 Sư Vạn Hạnh, Pleiku, Gia Lai

Tel/Zalo: 089 8888 373

- KHO SÀN GỖ KON TUM 61 Phạm Văn Đồng, Lê Lợi, Kon Tum

Tel/Zalo: 091 8888 137

- KHO SÀN GỖ ĐẮK LẮK 105 Hà Huy Tập, Tân Lợi, Buôn Ma Thuột, Đắk Lắk.

Tel: 091 8888 945 - KHO SÀN GỖ BUÔN MA THUỘT 38 Nguyễn Hữu Thọ, Tân An, Buôn Ma Thuột, Đắk Lắk.

Tel: 0855 8888 02

- KHO SÀN GỖ ĐẮK NÔNG 30 Lê Lai, Nghĩa Trung, Gia Nghĩa, Đắk Nông

Tel: 090 8888 537

- KHO SÀN GỖ QUY NHƠN 114 Đào Tấn, Nhơn Bình, Qui Nhơn, Bình Định

Tel: 090 8888 776 - KHO SÀN GỖ HOÀI NHƠN 348 Quang Trung, Tam Quan, Hoài Nhơn, Bình Định

Tel: 0965 8888 43 - KHO SÀN GỖ BÌNH ĐỊNH 1213 Trần Hưng Đạo, Đống Đa, Quy Nhơn, Bình Định

Tel: 082 8888 920

- KHO SÀN GỖ PHÚ YÊN 220 Nguyễn Văn Linh, Phú Lâm, Tuy Hòa, Phú Yên

Tel: 090 8888 057 - KHO SÀN GỖ TUY HÒA 138 Lê Lợi, Phường 4, Tuy Hòa, Phú Yên

Tel: 082 8888 078

- KHO SÀN GỖ QUẢNG NGÃI 180 Hai Bà Trưng, Lê Hồng Phong, Quảng Ngãi

Tel: 091 8888 274

- KHO SÀN GỖ QUẢNG NAM 130 Nguyễn Văn Trỗi, Tân Thạnh, Tam Kỳ, Quảng Nam

Tel: 094 8888 130

- KHO SÀN GỖ HUẾ 34 Hoàng Quốc Việt, An Đông, Huế, Thừa Thiên Huế

Tel: 0764 8888 27

- KHO SÀN GỖ QUẢNG TRỊ 399 Quốc Lộ 9, Đông Hà, Quảng Trị

Tel: 0969 8888 74

- KHO SÀN GỖ QUẢNG BÌNH 545A Lý Thường Kiệt, Đồng Phú, Đồng Hới, Quảng Bình.

Tel: 094 8888 973

- KHO SÀN GỖ NGHỆ AN 52, Phạm Đình Toái, Hà Huy Tập, Vinh, Nghệ An

Tel: 091 8888 480 - KHO SÀN GỖ CỬA LÒ 350 Phạm Nguyễn Du, Nghi Hải, Cửa Lò, Vinh, Nghệ An

Tel: 0902 8888 37 - KHO SÀN GỖ QUÁN HÀNH Đ. Xã Đoài, Khối 6, Nghi Lộc, Nghệ An

Tel: 094 8888 231

- KHO SÀN GỖ LONG AN 90 Hùng Vương, Tân An, Long An

Tel: 091 8888 097

- KHO SÀN GỖ TIỀN GIANG 286-288 Nguyễn Công Bình, Mỹ Tho, Tiền Giang

Tel: 079 8888 282

- KHO SÀN GỖ BẾN TRE 712 Ấp Hòa Trung, Sơn Hòa, Châu Thành, Bến Tre.

Tel: 083 8888 065

- KHO SÀN GỖ VĨNH LONG 94 Ba Tháng Hai, Phường 1, Vĩnh Long

Tel: 092 8888 955

- KHO SÀN GỖ ĐÔNG THÁP 68 Vành Đai, tổ 18, Hoà Khánh, Hòa An, Cao Lãnh, Đồng Tháp

Tel: 0898 888 937

- KHO SÀN GỖ CẦN THƠ 218 Đường 3-2, Hưng Lợi, Ninh kiều, Cần Thơ

Tel: 091 8888 677

- KHO SÀN GỖ SÓC TRĂNG 417 Tôn Đức Thắng,Phường 5, Sóc Trăng

Tel: 083 8888 417

- KHO SÀN GỖ BẠC LIÊU 42A Tôn Đức Thắng, Khóm 7, Phường 1, Bạc Liêu.

Tel: 091 8888 294

- KHO SÀN GỖ CHÂU ĐỐC 140 Trưng Nữ Vương, Châu Phú B, Châu Đốc, An Giang.

Tel: 098 888 4640

- KHO SÀN GỖ KIÊN GIANG 187 Quang Trung, P. Vĩnh Quang, Rạch Giá, Kiên Giang.

Tel: 0817 8888 23 - KHO SÀN GỖ PHÚ QUÝ Lô P1-13 Đường 3/2, P. An Hoà, Rạch Giá, Kiên Giang.

Tel: 091 8888 316

- KHO SÀN GỖ PHÚ QUỐC 38 Mạc Cửu, Khu Phố 4, Dương Đông, Phú Quốc, Kiên Giang

Tel: 091 8888 402

- KHO SÀN GỖ NAM ĐỊNH 308 Trường Chinh, Vị Xuyên, TP Nam Định

Tel: 090 8888 534

- KHO SÀN GỖ HẢI PHÒNG 209 Bùi viện, Vĩnh Niệm, Lê Chân, TP Hải Phòng

Tel: 084 8888 209 - KHO SÀN GỖ VIỆT PHÁT Lô B06, Anh Dũng 1, Dương Kinh, TP Hải Phòng

Tel: 091 8888 964

- NHÀ MÁY SẢN XUẤT SÀN GỖ KCN 7 MẪU, Tân Uyên, Bình Dương.

Tel: 091 8888 820 - NHÀ MÁY SẢN XUẤT TẤM ỐP PVC Lô 8 đường số 9 CCN Hải Sơn, Đức Hoà, Long An.

Tel: 0913 8888 23 - NHÀ MÁY SẢN XUẤT GỖ NHỰA WPC KCN Châu Sơn, Lê Hồng Phong, Phủ Lý, Hà Nam.

Tel: 088 666 7766 - NHÀ MÁY SẢN XUẤT SÀN GỖ CÔNG NGHIỆP KCN Phú Thành, Xã Phú Thành, Lạc Thủy, Hòa Bình.

Tel: 0913 696 393 - XƯỞNG SẢN XUẤT TẤM THAN TRE 221/3 Phan Huy Ích, Phường 14, Gò Vấp, HCM.

Tel: 091 8888 965 - NHÀ MÁY SẢN XUẤT SÀN NHỰA Số 5, KCN Hải Sơn, Đức Hòa, Long An.

Tel: 091 8888 820

TƯ VẤN MIỄN PHÍ: 1800 6121 - Hotline: 0913.8888.01 - 0913.8888.02 (Viber / Zalo) - LIÊN HỆ

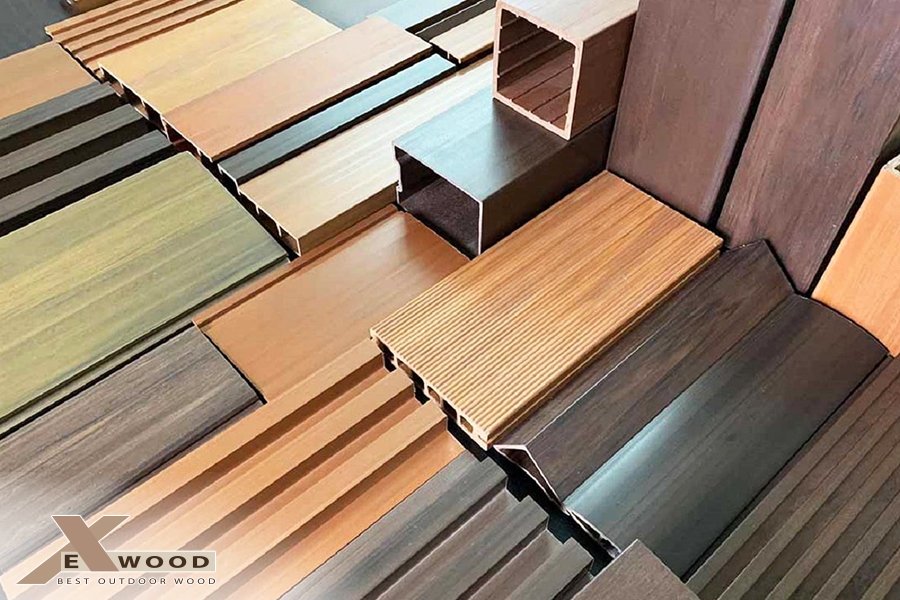

EXWOOD Decking

ExWood wpc : Exterior Wood - Wood Plastic Composite and is a crystallized product from wood and plastic. EXWOOD WPC Factory in Vietnam

EXWOOD WPC was born to replace natural wood, using PE/PP plastic pellets and wood fibers produced by extrusion and injection molding, without any glue in the products. Therefore it does not contain toxic substances. EXWOOD is used to decorate the exterior of your home with many uses such as making pool decks, sunshades, fences, pergola….

If you are looking for a new material for exterior designs, EXWOOD is a product that is completely suitable for the conditions of outdoor products. EXWOOD is distributed evenly across the country from north to south.

EXWOOD WPC: WOOD AND PLASTIC COMPOSITE

Modern building materials should not only be aesthetically pleasing, but also practical, easy to handle and maintain, and most importantly, economical. Many enterprises are working in the field of inventing new materials, focusing research mainly on the combination of various substances, and among them such a promising novelty as wood mixtures can be distinguished -polymer (WPC) .

WPC is often called wood plastic composite and those who like to flaunt their English knowledge call it wood plastic composite. From these names it becomes clear that it is a combination of plastic and wood in a molten state, followed by solidification of the final product. Composite wood is an alternative to expensive woods, while significantly improving performance compared to any wood or plastic. In the light of the modern fashion for environmentally friendly materials, EXWOOD WPC is a necessary innovation in materials used for making cladding, flooring, manufacturing sheet and bar shape patterns as well like many other construction and finishing wood materials. EXWOOD WPC has received the widest application in the field of rooftop board (decking) production.

The most common application of EXWOOD WPC is flooring or flooring

Properties and characteristics of EXWOOD WPC

WPC consists mainly of wood fibers, its role is successfully performed by waste from the woodworking industry and plastics as binding substrates. Thus, the resulting material combines all the useful properties of modern polymers and natural wood.

EXWOOD WPC - at the factory

EXWOOD WPC composition and production

Let's look at the composition of WPC in more detail, then its changes can be traced from the beginning of production to the present, and now it looks like this: crushed wood filler, creating block main quantity for the product, bound by one of three polymer types. The purpose of the finished product determines the choice: polypropylene, polyvinyl chloride (PVC) or classic polyethylene. Plastic with fillers binds and turns into a single mass.

Additives are actively used in the production of EXWOOD WPC

Various additives are needed to give the mixture the desired performance characteristics. Their role in the compound is performed by products of the chemical industry:

- Colorants for coloring

- Modifiers to enhance strength and stiffness

- Lubricants for better moisture resistance and faster extrusion

- Foaming agent to create brightness and smoothness of the surface

- Antibacterial agent to maximally resist the effects of biological factors.

The quality of wood plastic composite is shown in:

Authentic wood patterns, textures and colors

Resistant to weather changes

characteristic aroma

Safe for the environment and for consumers.

EXWOOD WPC features:

High moisture resistance, so you should forget about the problem of water flooding the floorboards;

durability and wear resistance, thanks to which EXWOOD WPC products are not afraid of constant loads, impacts and abrasion. Shoes, animal claws, fallen objects do not leave obvious marks on the surface. In addition, even when wet, EXWOOD WPC flooring does not slip, which is very important when used on floors, steps and of course patios, open areas and even EXWOOD wooden grates for paving garden paths (wooden floors in the garden)

Heat resistance and ability to withstand harsh weather conditions;

resistant to insects, fungi and rot-causing bacteria;

ease of processing and installation (an example of the construction of an EXWOOD WPC terrace);

EXWOOD WPC is a sustainable synthetic wood, and at the same time:

Reliable, durable and beautiful;

No maintenance required other than dusting. Scraping, varnishing, painting and other manipulations are the whims of the tree, wood-polymer mixtures simply do not need them;

Economically, there is simply no point in comparing EXWOOD WPC to natural wood in terms of cost, and plastic becomes more expensive over time due to the fact that it requires frequent repairs and replacement. That is, a wood-polymer composite that will easily serve you for a quarter of a century will survive several changes in plastic and wood, due to which its cost in the overall account is reduced several times.

The variety of WPC products is truly from EXWOOD WPC's range of uses

Such undoubted advantages have led to the use of EXWOOD WPC in the construction sector and even in the interior decoration of cars and yachts, and due to its excellent water resistance, it is used for construction erecting structures that are constantly in contact with water or are constantly in it: swimming pool decks, docks and docks, stairs, building decks for ships and even yachts, wall cladding, making fences, flower trellises , shelter, hut...

EXWOOD WPC for multi-function outdoor decoration applications is a material that is friendly to any location you want.

|  |

| WPC garden decking is great for paving open areas and terraces, as well as garden paths | Modern partitions or wall panels made of WPC have successfully replaced vinyl, metal and cement partitions |

| | |

| WPC flower beds are becoming increasingly popular due to their durability and ease of installation. | Fences and fences made of WPC do not differ in appearance from wooden fences, but do not require regular processing and replacement of rotten boards |

In home construction, EXWOOD WPC becomes the number 1 material when installing floor coverings, carports, dance floors, porches, terraces and fences. In addition to everything, excellent garden structures are obtained from liquid wood: arbors, terraces, paths, fences, gates - and all thanks to its resistance to temperature, ultraviolet sunlight and in harmony with the ecological environment. And this type of facade panel is always designed by architects using WPC material if the owner wants to receive pride at first sight.

Heat and moisture resistant, easy to install and moreover, the eco-friendly EXWOOD WPC becomes a great alternative for aquarium eye liners and also makes bird's nest houses. It also makes excellent window sills and table tops, furniture and doors of any type EXWOOD WPC is also suitable

The most popular EXWOOD WPC decorative material is flooring, also known as flooring. Parquet is used to create floor coverings in the interior and outdoors, as well as in rooms that often have high humidity: bathrooms, saunas, bathrooms. All the positive qualities of EXWOOD WPC are active when using it for the exterior decoration of buildings: balconies, terraces, mining roofs, porches, piers, piers and decks have been mentioned access.

The terrace board is a traditional masterpiece with an ideal exterior deck configuration. In addition, manufacturers recommend using hollow or solid floor configurations for different types of expected loads to reduce costs while still meeting the needs.

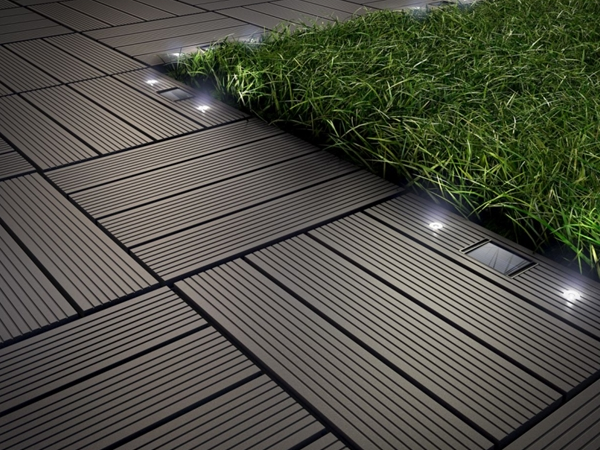

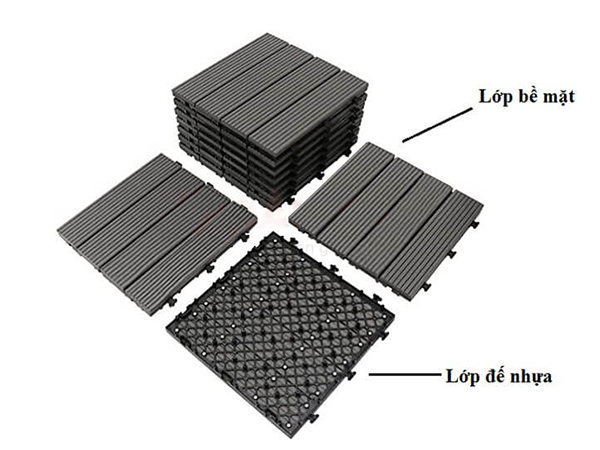

Also very popular is an EXWOOD WPC product called plastic wood grating for garden flooring. Outwardly, it looks like a tiled floor with sections about 30 x 30 cm, but the wooden floor itself is made of a plastic substrate, on which EXWOOD boards are attached. The special fasteners of the underlayment make installation and reassembly of the floor easy and simple, suitable for seasonal buildings, playgrounds or private suburban areas.

|

| |

| DIY EXWOOD WPC tiles - garden flooring can have two layers: base and front | The garden path is paved with DIY EXWOOD WPC tiles - balcony flooring |

|  |

| DIY EXWOOD WPC tiles are the perfect solution for large patios | DIY EXWOOD WPC Tiles are also a great choice for an open area in the garden |

EXWOOD WPC Where does this wonderful material come from?

WPC was invented in 1909 by Leo H. Baekeland, first saw finished products in the United States during the 1960s, mainly in window and door frame applications and it was more than 50 years later that WPC became available. made in Vietnam.

In 2012, EXWOOD WPC was produced in Vietnam, mainly flooring, complete with enough molds. From 2015 to the present, the manufacturer received all molds ordered by customers for immediate production at the prototyping stage.

EXWOOD WPC received a patent for the copyright of synthetic wood plastic objects from Vietnam, thanks to which the EXWOOD brand was created. Now you can clearly see all the prerequisites for a Vietnamese brand idea. From its conception, the new WPC building material was not only a novelty but also stood on the brink of innovation. unrealistic, until gaining the trust of consumers for a long time. EXWOOD WPC is perfectly suitable for weather conditions from north to south and coastal areas.

EXWOOD WPC production technology requires strict compliance with technological processes and high quality raw materials. The innovative processes and improvements in production technology, and then the stable source of materials, have lasted until now and the finished products have received recognition from Vietnamese consumers,

EXWOOD WPC factory has received export orders to the EU, US and Middle East markets. Always receive production orders according to design requirements and demand for export goods.

TAX FREE SERVICES:

– Survey, measurement, estimate - quote.

– Consultation to view samples at home 24/7 (from 7:00 a.m. to 9:00 p.m., Monday to Sunday)

– Provide samples to check product quality, only from C.O & C.Q

☎️ Hotline: 1800 6121

We always welcome all customers to visit the factory

ExWood WPC, exclusive brand belongs to Hoang Gia Nam Viet Co, .Ltd

.png)